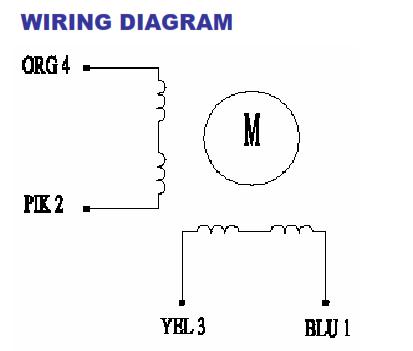

Determining which wires from the stepper motor belong to the same coil. A pair of wires from one coil of the motor gets connected to A- and A+ and the other to B- and B+. Make sure that you do not connect stepper motors with a current rating of more than 3.5 A to the driver.Ī+,A- and B+,B- are the connections for the 4 wire bipolar stepper motor phases or coils. However, they have some major differences that I’ll list in the comparison table below. The TB6560 stepper motor driver can easily be confused with TB6600 model since these drivers can both be controlled using the same connections and code. Difference between TB6600 and TB6560 Stepper Motor drivers. Other specifications can differ slightly depending on the manufacturer and therefore you should always check the datasheet of your driver before use. The driver has over-current, under-voltage shutdown, and overheating protection. Also, the TB6600HG only supports up to 1/16 microstepping while the TB67S109AFTG goes up to 1/32. These chips are almost similar in performance and specifications but the TB6600HG is larger and has a higher peak current rating of up to 5A compared to the smaller TB67S109AFTG chip with a peak current rating of 4A. However nowadays many of these drivers have a TB67S109AFTG IC also made by Toshiba. The TB6600 Stepper motor driver was originally built around TB6600HG stepping motor IC made by Toshiba.

TB6600 Stepper Motor driver hardware description.

#Stepper motor arduino wiring how to

In this tutorial I’ll describe the TB6600 motor driver hardware in detail and also demonstrate how to control the driver with Arduino. The TB6600 stepper motor driver is used to control larger two-phase bipolar stepper motors like NEMA 23 motors used in 3D printers, CNC machines and robots.

0 kommentar(er)

0 kommentar(er)